AU-EMPA

The Auburn University Electron Microprobe Analysis Lab (AU-EMPA)

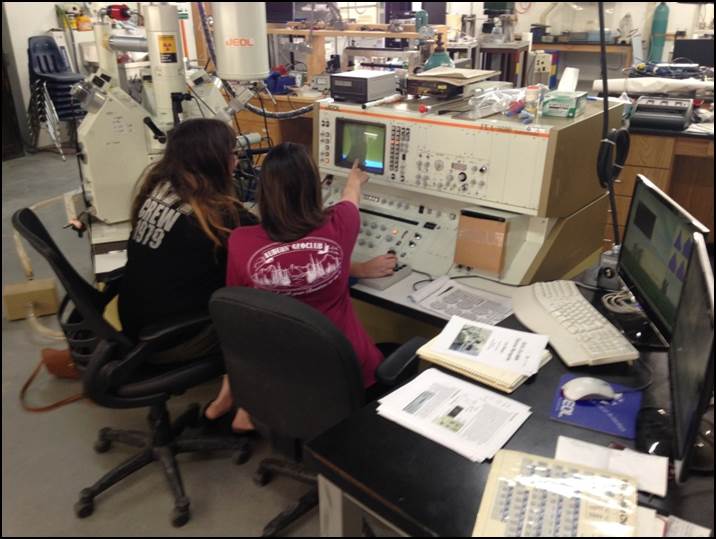

General information: The Auburn University Electron Microprobe Analysis Lab (AU-EMPA) hosts a JEOL JXA-8600 electron microprobe equipped with a tungsten electron gun, 4 wavelength-dispersive spectrometers for quantitative analysis, Si-Li energy-dispersive spectrometer detector for qualitative analysis, and BSE and SE detectors for imaging. This electron microprobe can achieve a high spatial resolution (0.7-1.0 µm beam size) and relatively low detection limit, as low as 50-100 ppm for some elements. The in situ analytical volume is typically a few cubic microns, and can be as small as a cubic micron for dense material. We offer a wide range of in situ analytical applications, and we have a strong commitment to provide precise and accurate results.

Samples: Samples must be either mounted on petrographic thin sections (27x46 mm [1.80x1.06 in]) or epoxy round mounts (25 to 30 mm [1 to 1¼ in]). Irregular or non-conventional sized samples can be accommodated (contact the lab manager to discuss accommodation of non-conventional samples). The sample must be extremely well polished to ensure accuracy of the results; we recommend a finish with at least a 0.2 µm colloidal alumina, diamond power, or similar polishing material. Only dry samples can be utilized for analysis (the analytical chamber operates under high vacuum conditions, and the instrument has no provision for handling wet or other volatile-rich samples). Sample preparation can be made in-house on demand (if sample preparation is required, please discuss costs and the time required with the lab manager).

Analytical capabilities: The instrument is equipped with 6 different monochromators that permit the analysis of any element from beryllium (Be) to uranium (U). Analysis of light elements (Z ≤ 8: Be to O) is possible, although such light elements present some analytical challenges. The instrument is fully automated and uses the Geller Microanalytical system for both imaging (dPict) and quantitative analysis (dQuant). Examples of applications include characterization of chemical composition and variation in a large variety of geological materials (silicates, sulfides, carbonates, phosphate, glass…) and material sciences (alloys, ceramics, steels…), chiefly for major and minor elements. A typical analysis of 8 elements (2 per spectrometer) can be completed in 2-3 minutes, but it can take longer (>10 min) for larger sets of elements and/or for analysis of minor and trace elements that require longer counting times (along with higher beam current). Based on counting statistics, relative errors are estimated to be <1-2% at the >10 wt-% level, 2-5% at the 10 to 3 wt-% level, 5-10% at the 3 to 1 wt-% level and >20% at <0.5% level; these can be improved somewhat by increasing the counting time or beam current. The instrument is also capable of BSE or SEM imaging, and also element mapping by wavelength-dispersive spectroscopy.